Products

Details

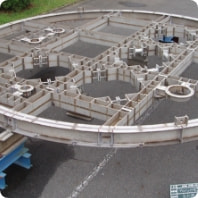

Underground regulating pondage

Application: Underground regulating pondage Field: Flood control (rainwater)

Overview/construction method /effect

Purpose of development Releasing water underground during peak river flow periods prevent flooding and inundation damage in the basin temporarily is one of the(regulating pontage)mechanisms to protect communities from flood damage caused by typhoons, heavy rains, and localized torrential rains.

Effect of using stainless steel

- ①To prevent deterioration of the landscape due to steel corrosion and to create an aesthetically pleasing waterfront space.

- ②Maintenance free is desirable due to the difficulty of location to be maintained.

- ③To prevent the elution of corrosive metals and to conserve a clean groundwater environment.

Example: Case Study

Sewage trunk line control pond

River regulating pondage

Project details

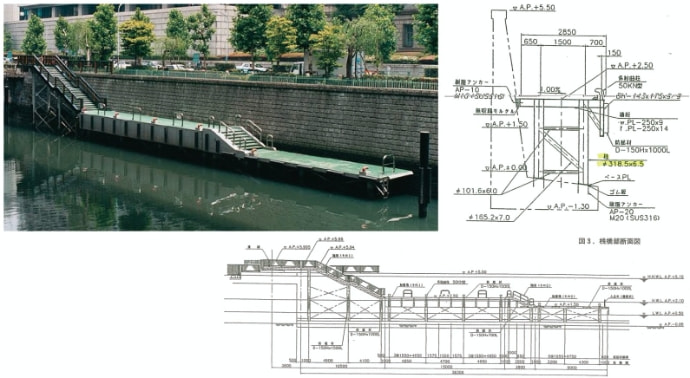

Disaster-prevention wharf

Application: Disaster-prevention wharf Field: River

Overview/construction method /effect

Purpose of development To create a comfortable and pleasant waterfront space and to contribute to the improvement of the disaster-prevention function, including smooth water carriage of materials and people who are unable to return home in the event of disaster.

Effect of using stainless steel

- ①To prevent deterioration of the landscape due to steel corrosion and to create an aesthetically pleasing waterfront space.

- ②Maintenance free is desirable due to the difficulty of the location to be maintained.

- ③It has excellent deformation characteristics against ship berthing and collisions with objects flowing down rivers.

Example: Case Study

Tokiwa Bridge over the Nihombashi River

Chiyoda Ward Office

Ichibee River Bank along the Kanda River

Project details

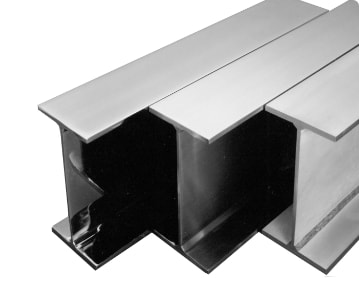

Exterior material-receiving steel frame

Application: Exterior material-receiving steel frame Field: Construction : exterior

Overview/construction method/effect

Reduction of maintenance cost Using stainless steel’s excellent corrosion resistance and durability we are able to handle the details in hard to maintain areas.

Design quality Due to various types of stainless-steel finishes including base surface, hairline, mirror surface, buffing, and etching, a wide variety of designs are available.

Example: Case Study

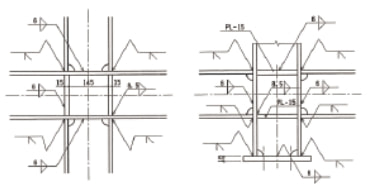

SUS304 glass block receiving steel frame

There are difficulties maintaining steel frame after glass block installation

⇒ Using stainless steel's excellent corrosion resistance and durability can reduce maintenance cost.

Pillar and Beam Components:

SUS304 BH-175×175×8/12

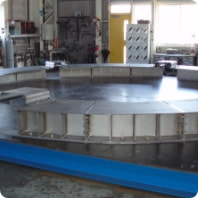

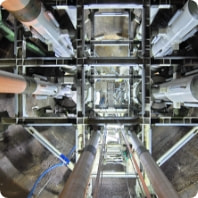

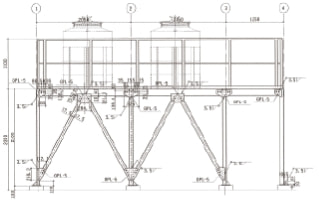

Equipment pedestal

Application: Equipment pedestal Field: Construction and equipment

Case example

Overview

- Materials used

- : SUS304

- Structure overview

- : brace structure

- Live load

- : 2,900N/㎡

- Special load

- : tank load

- Earthquake-proof coefficient

- : 1.0

- Column

- Bent C-150×75×6

- Girder

- Bent C-150×75×6

- Beam

- Bent C-150×75×6

- Column

- Bent C-150×75×6

Bent L-75×75×6 - Brace

- Bent L-75×75×6

- Floor

- C.PL-4.5

Design Standard and its Explanation

Temporary assembly inspection status (before acid cleaning treatment)

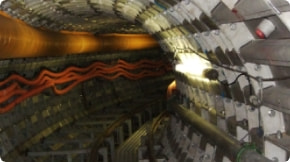

Steel frame of hot springs facility

Application: Steel frame of hot springs facility Field: Construction: hot springs facility

Overview/construction method/effect

Effect of using stainless-steel

- ①Stainless-steel for building structures (JIS G4321) can be used as the building’s steel frame structural material.

- ②It is possible to select an optimum material based on the individual environmental conditions of the hot springs facility.

- ③It is possible to create a clean, bright, and comfortable space.

Example: Case Study

Large communal bath of Hotel Kirishima Castle

【 Background 】- ・After construction of the building with galvanized steel frames (pipe trusses), corrosion considered to be attributable to sulfur occurred in the hot springs.

- ・The building was modified by using large pieces of laminated wood, but rotting was caused by wood-destroying fungi, and it became necessary to rebuild and modifying again.

- ・Indoor temperature: 25 to 40°C, - indoor humidity: 60 to 80%, hot spring water: simple sulfur spring with a pH level of 6.3 (neutral hot water)

- ・Under the temperature, humidity, hydrogen sulfide, and pH conditions that serve as corrosion factors, SUS304A was used, and the stainless-steel structure created brighter, much comfortable, and cleaner space.

Project details

Base for greening of exhaust port wall surface

Application: Base for greening of exhaust port wall surface Field: Construction: equipment

Overview/construction method/effect

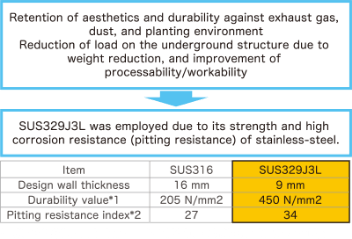

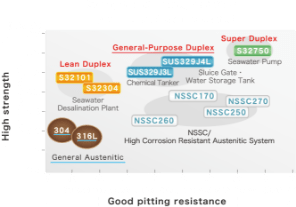

Effect of employment of two-phase stainless-steel (SUS329J3L)

- ①Utilizing high strength characteristics of stainless steel by thin-walled design reduced weight (reduction of steel used).

- ②Reduction of the maintenance man-hours (life cycle cost) by high corrosion resistance.

Example: Case Study

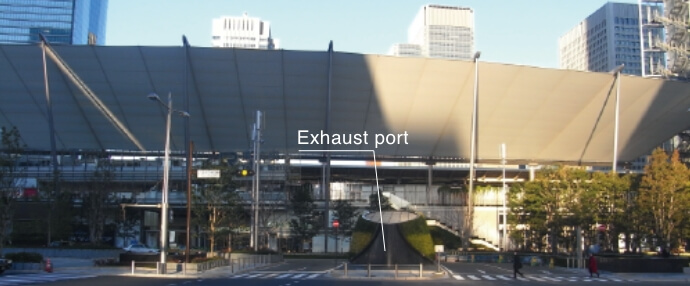

Exhaust port at the Yaesu Gate of Tokyo Station

【 Selection of steel type 】

・Wall surface panel PL-9

・Foundation steel frame BH-500×250×9/9

・Ceiling louver BT-100×100×9/9

Exhaust port completion status

Project details

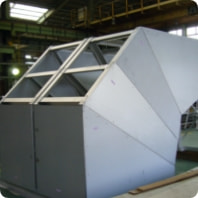

Private power-generation equipment in the event of a disaster:

Exhaust port steel frame

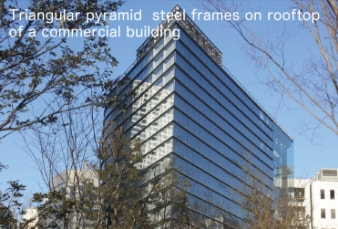

Application: Private power-generation equipment in the event of a disaster: exhaust port steel frame Field: Construction: equipment

Overview/construction method/effect

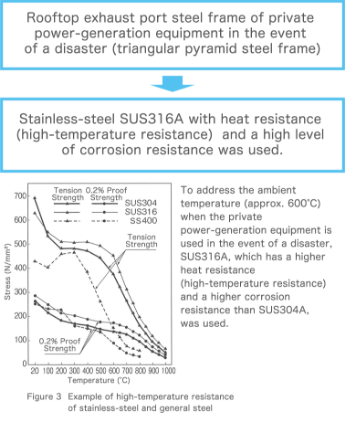

Effect of employment of stainless-steel (SUS316A)

- ①Stainless-steel for building structures (JIS G4321) is used as the building’s steel frame structural material.

- ②Stainless-steel with excellent high-temperature resistance has been used to ensure durability at high temperature range.

- ③Maintenance was freed due to high corrosion resistance of stainless steel.

Example: Case Study

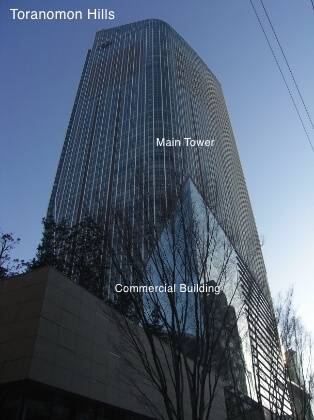

Block III in Class-2 urban redevelopment project of Loop Highway 2 in the Shimbashi-Toranomon District

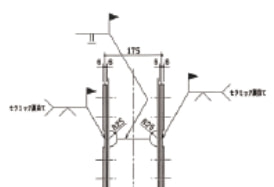

[ Main components of triangular pyramid steel frame ]

Column ) SUS316A BH-200x200x8/12

Beam ) SUS316A BH-200x200x8/12

Brace ) SUS316A L-75x75x9

Total 6.1 tons

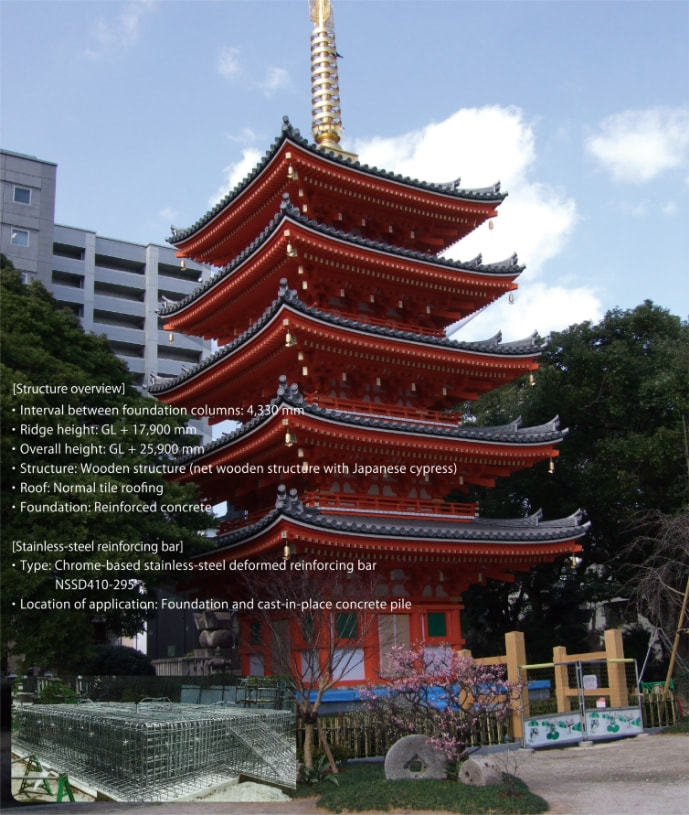

Application of stainless-steel reinforcing bars to a traditional building

Application:

Application of stainless-steel reinforcing bars

to a traditional building

Field: Construction: steel frame

Overview/construction method/effect

Effect of use of stainless-steel reinforcing bars

- ①Stainless-steel reinforcing bars can alleviate the problem of concrete neutralization in addition to reinforcing bar corrosion due to the cracking of concrete.

- ②In terms of life cycle cost, it is possible to significantly reduce the repair and maintenance costs associated with cracking, which leads to an economical rationality.

- ③By using materials certified by the Minister of Land, Infrastructure and Transportation, it is possible to design structures and conduct processing and construction in the same manner as with ordinary reinforcing bars.

Example: Case Study

Five-story pagoda of Tochoji Temple (Hakata Ward, Fukuoka City)

which are used in the foundation and piles of this five-story pagoda

in a fusion of traditional Japanese cypress wood structures

and state-of-the-art stainless-steel technology in order to support the traditional

building far into the future.

Project details

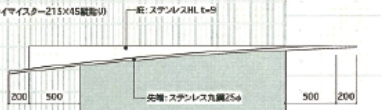

Stainless-steel pent roof

Application: Stainless-steel pent roof Field: Construction: pent roof

Overview/construction method/effect

Design quality The number of elements that decorate the façade of a small building is limited. In this building, the stainless-steel plate and stainless-steel rods welded at the end give an impression of the brim of a lady’s hat. (Design: K3 Institute Inc.)

Example: Case Study

SUS304 stainless-steel pent roof

Project details

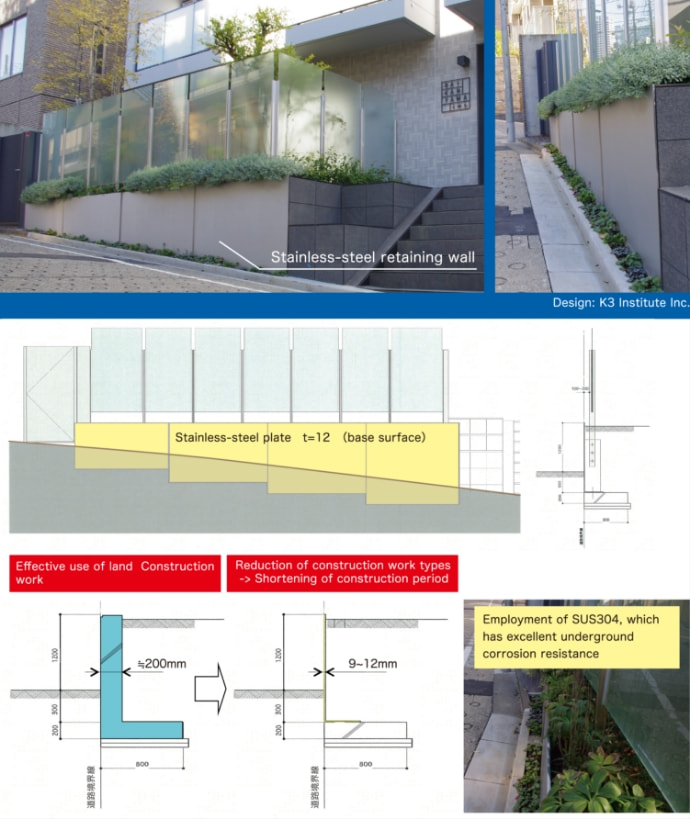

Stainless-steel retaining wall

Application: Stainless-steel retaining wall Field: Construction: exterior

Overview/construction method/effect

Effective use of land In the construction of an urban building where the site area is limited, a little space for planting enriches the façade.

Design quality Due to various types of stainless-steel finishes including base surface, hairline, mirror surface, buffing, and etching, a wide variety of designs are available.

Corrosion resistance Stainless-steel has an excellent underground corrosion resistance and helps retain the beautiful appearance for many years.

Example: Case Study

SUS304 Stainless-steel retaining wall

Project details

Welded Shapes Steel

▶View More